2021 wholesale price Beverage Filling Machine - Carbonated soft drink filling machine line – Higee

2021 wholesale price Beverage Filling Machine - Carbonated soft drink filling machine line – Higee Detail:

Carbonated soft drink 3 in 1 filling machine line

This series of filling equipment is PET bottle carbonated beverage filling machine with washing filling capping in one machine, with reasonable structure, safe, reliable and easy maintenance.

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

Parameters:

|

Model |

DCGF 8-8-3 |

DCGF 16-12-6 |

DCGF 16-16-6 |

DCGF 16-16-5-2A |

DCGF 18-18-6 |

DCGF 24-24-8 |

DCGF 32-32-8 |

DCGF 40-40-10 |

DCGF 50-50-15 |

DCGF 60-60-15 |

DCGF 72-72-18 |

|

|

Capacity 0.5L/bottle/h |

2000 |

3000-3500 |

4000-4500 |

5000-5500 |

5500-6500 |

8000-850000 |

12000-13000 |

15000-16000 |

18000-20000 |

21000- |

28000- |

|

|

Filling precision |

<= +2 mm (Liquid level) |

|||||||||||

|

Filling pressure |

<= 0.4 Mpa |

|||||||||||

|

PET Bottle specification |

Bottle Diameter 50-115 mm Height 160-354m0m |

|||||||||||

|

Suitable cap shape |

Plastic Screw Cap or Crown Cap |

|||||||||||

1. Air conveyor

2.Automatic carbonated soft drink washing/filling/capping 3-in-1 monoblock

It’s especially design to fill carbonated beverage into plastic bottle, the process chart is below:

Rinse the empty bottle with clean water filling carbonated soft drink into the plastic bottle capping the filled bottles with screw type cap

This carbonated soft drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic washing, filling and capping. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation, etc

Features:

● With bottle neck clipping transmission structure, the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts.

● With Gravity filling theory, filling speed is quick and precision is high; the filling level is adjustable.

● With spring type washing clipper, empty bottles are turned 180°along the guiding roll for inside rinsing; the washing nozzle adopts plum blossom shape multiple holes to rinse the bottle bottom, washing efficiency is high.

● Capping machine adopts France technology, the capping is by magnet torque; the cap catching adopts twice catching to ensure the veracity. The capping force is adjustable, constant torque capping will not damage caps and the cap is good sealed and reliable.

● The whole machine is operated by touch screen, controlled by PLC and frequency convertor etc., with functions of no bottle no cap feeding, waiting when lack of bottles, stopping if bottle is blocked or no cap in cap guiding pipe

4. Belt conveyor

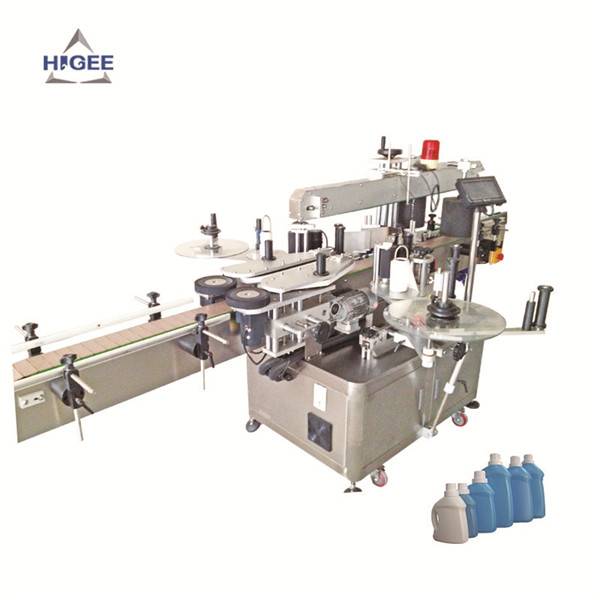

Product detail pictures:

Related Product Guide:

Cooperation

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for 2021 wholesale price Beverage Filling Machine - Carbonated soft drink filling machine line – Higee , The product will supply to all over the world, such as: Philippines, Panama, London, We have customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.