2021 wholesale price Tablet Filler - Automatic Capsules Counting Filling Line – Higee

2021 wholesale price Tablet Filler - Automatic Capsules Counting Filling Line – Higee Detail:

Bottle Unscrambler

Parameters

|

Item |

Auto bottle unscrambler |

Turning table |

|

Power supply |

Single phase, 220V |

|

|

Power consumption |

0.25kw |

0.2kw |

|

Feeding speed |

20-80 Bottles/minute |

60-80 bottles/min |

|

Total Weight |

200kg |

100kg |

|

Dimensions |

1200×1150×1300mm |

650 x 650x 1000mm |

|

Automation grade |

Fully automatic |

Need manually put the bottles |

|

Function |

Bottle arranging and feeding |

Bottle feeding and collecting |

Automatic Capsule Counting Filling Machine

Description

Automatic Electronic counting machine is special for counting tablets, soft gelatin, hard capsule and chewing gums, etc. This machine adopts 8 sets imported counting sensor for counting with 8 Guiding Way and two head. The advantage of the machine is no need change mould when you change the counting object, only adjusting the counting table height by Easy Adjust wheel. The machine comes with Touch screen operation and PLC Control for convenient running.

Parameters

|

Items |

Parameters |

|

Application |

Filled capsule(00-5#) Soft Gelatin capsule chewing gum Tablet other solid object under machine range |

|

Hopper Volume |

20L |

|

Capacity |

20-30bottles(50-100 pcs/bottle)/min |

|

Filling Quantity |

2-9999pcs/bottle (adjustable) |

|

Bottle Size |

Diameter: 30-75mm Height:40-250mm |

|

Counting Size |

Thickness: 3-10mm Diameter: 3-22mm Length: 3-30mm |

|

Compressed air |

0.6Mpa |

|

Machine Weight |

250kg |

|

Machine Size L × W × H (mm) |

1360x1300x1700mm |

Details

Automatic Desiccant Inserting Machine

Description

Tablet and capsule are easy to go moist, so it is necessary to put the desiccant into the container to keep medicine away from moisture in order to improve reliability of guarantee period. The machine applies automatic controlling system to take the place of the previous manual operation. The machine can automatically cut the belted desiccant and insert the desiccant bag into the container accurately and speedily. It is available for bottles and pots made of different materials. It features double-lane photoelectric positioning, intelligent feeding length controlling and automatic adjustment of accumulated length error. The electronic controlling system ensures the machine starts when bottles reach working position and stops when bottles are insufficient automatically. The product conforms to the requirements of GMP completely.

Parameters

|

Items |

Parameters |

|

Bottle Size |

20-300ml |

|

Output |

40-100bottles/min |

|

Power Supply |

220v 60Hz |

|

Power |

0.85kw |

|

Overall Dimension |

1150*800*1900mm |

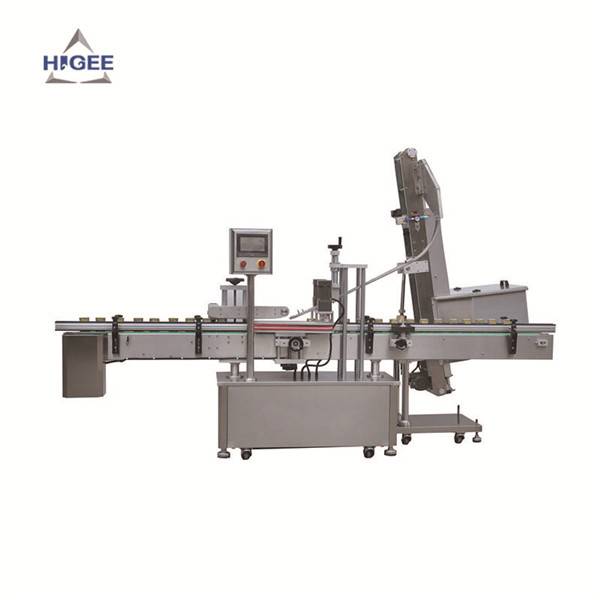

Automatic Capping Machine

Description

The screw capper is available for various bottles and its changeover is fast and easy. The machine overthrows conventional means of arranging cap by electromagnetic oscillation but arranges caps pneumatically to avoid noise pollution and reduce electric power consumption. It also provides international brand PLC controls, variable frequency controls and photoelectric controls. The machine is incorporated with the device of arranging and lifting cap and a big capacity of cap hopper, so less cap feeding times reduces labor intensity. Generally operators can grasp fluently. The machine conforms to the requirements of GMP completely.

Parameters

|

Items |

Parameters |

|

Size of bottles |

20-500 ml |

|

Output |

50-150 bottles/min |

|

Diameter of caps |

φ20-65 mm |

|

Diameter of bottles |

φ20-120 mm |

|

Power supply |

220V 60Hz |

|

Power |

1.5KW |

|

Overall dimensions |

2160*1050*1900 mm |

|

Weight |

650KG |

Detail

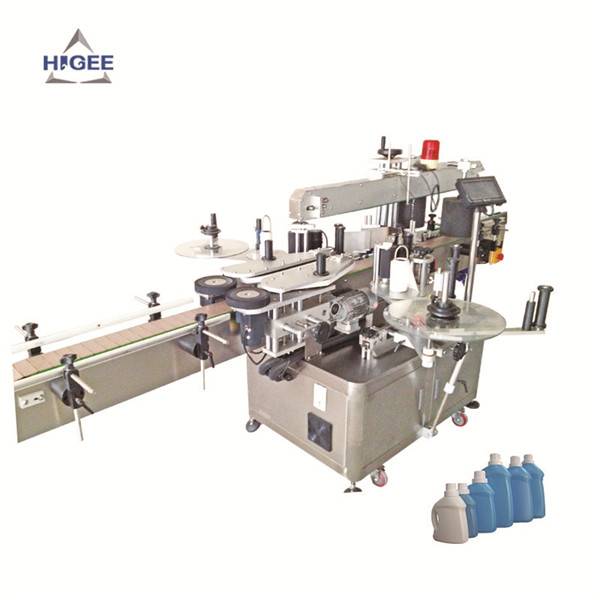

Automatic Sticker Labeling Machine

|

|

Product detail pictures:

Related Product Guide:

Cooperation

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of 2021 wholesale price Tablet Filler - Automatic Capsules Counting Filling Line – Higee , The product will supply to all over the world, such as: Barbados, Slovenia, Bhutan, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!