Chinese Professional Liquid Filling Machine - Energy drink filling machine – Higee

Chinese Professional Liquid Filling Machine - Energy drink filling machine – Higee Detail:

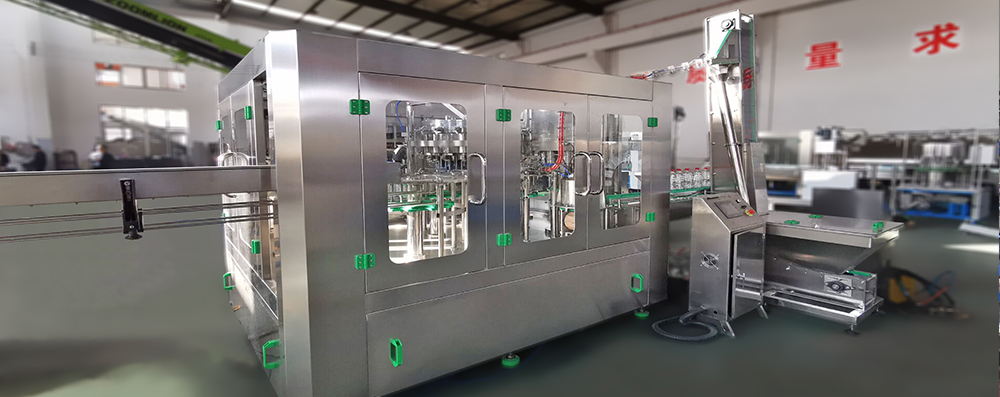

Energy Drink Filling Machine 3 in 1 Monobloc Production Line

Features:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

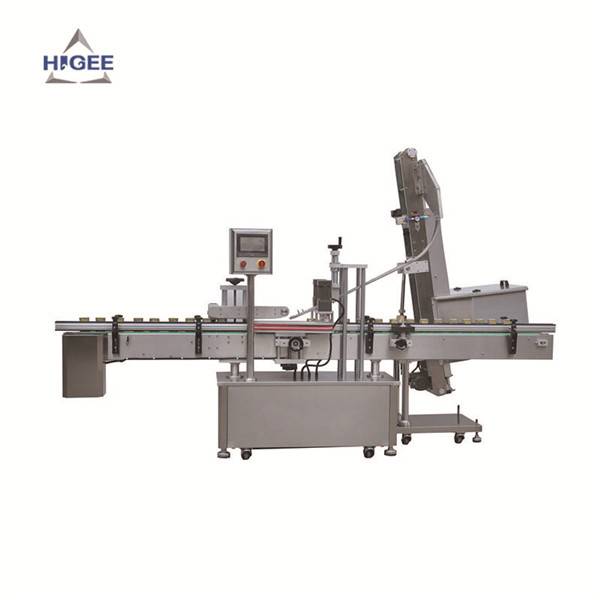

We can also equip the drink production line with water treatment equipment, pre-treatment mixer equipment system, and the packing system including shrink sleeve labeling machine, shrink packing machine etc.as one complete line.

1. Air conveyor

2.Energy drink filling machine (Washing/filling/capping 3-in-1 mono-block)

General description

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays water to rinse bottle inwall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet

Rinsing Part

● Except the down framework, the transmission parts and some parts that must be made of special materials. Other spare parts are made of stainless steel 304.

● The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

● The gripper is made of stainless steel, the position where hold the bottleneck is also made of stainless steel, compared with the traditional rubber gripper, it is much hygiene, durable, and no quick-wear parts, the screw parts of the bottleneck can avoid being polluted by the rubber gripper.

● The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water. There is a cover above the spray nozzle which can prevent water spilling; and there are regulatory recycle slot and recycle pipes under the nozzles.

● Rinsing time can be guaranteed for 2 seconds.

● By adjusting the height of the rotary parts to adapt for different bottle height

● The motivation is derived from the driven system in the framework passed by gear.

● The supplying of rinsing water is controlled by solenoid valve.

Filling Part

● Adopted famous brand anti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

● The rotate plate is made of stainless steel 304, large flat toothed bearing.

● The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of food grade stainless steel.

● The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling.

● The beverage supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

● Sliding bearing is adopted non-maintaining bearing, that can reduce the pollution of filling to the environment. Rolling bearing made of stainless steel, the sealing ring is made of EPDM material, plastics is made of UMPE.

● The motivation of the filler is derived from the driven system in the framework and passed by gear.

● The main drive adopts gear drive, with high efficiency, low noise, long life, easy maintenance, sufficient lubrication, grease can lubricate centralizing automatically, adopts transducer to the speed of main motor to control, the machine adopts step-less frequency conversion timing. The material for the whole platform and frame is carbon steel with stainless steel outside.

● The machine is automatically controlled by PLC, fault on line display, like bottle block, cap shortage etc.

● The key parts and electric elements of the machine are adopting import products.

Capping Part

This unit is the highest degree of accuracy of 3-in-1 machine, it is important for the machine to run stably and the product quality.

● Screwing capping head (the main parts which can assure the capping quality), the expert improve the design of magnetic steel, this improvement can reduce the defective rate of capping better and the traditional character of easy to set and adjust the torque of screwing capping head.

● The screwing capping head is dual-purpose design: it is suitable for flat cap and sport cap.

● The device which can take out the reverse cap and prevent the reverse cap passing is settled in the cap-falling guide.

● A group of photoelectric switches are settled on cap-falling guide. The machine will stop when there is no cap on the guide.

● A bottle inlet detect switch is settled on the screwing capper.

● There are aseptic nozzles between the transition poking wheel and filling parts to rinse the product rested in the bottleneck screw parts.

● There is a cap-lock cylinder in the joint between the cap-falling guide and poking cap plate. It is realize that no feeding no cap.

● By adjusting the height of the rotary parts to adapt for different bottle height.

● The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

● The main parts of the screwing capper are processed by the digital-control processing center

4. Belt conveyor

Product detail pictures:

Related Product Guide:

Cooperation

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for Chinese Professional Liquid Filling Machine - Energy drink filling machine – Higee , The product will supply to all over the world, such as: Naples, Nigeria, UK, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.