Factory wholesale Liquid Bottle Filling Machine - Automatic Still Water Filling Machine Line – Higee

Factory wholesale Liquid Bottle Filling Machine - Automatic Still Water Filling Machine Line – Higee Detail:

PET bottle Pure or Mineral Water 3 in 1 Rinsing Filling and Capping Machine Line

Features:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

Parameters:

| Capacity range | 3000BPH-42000BPH (based on 500ml PET bottle) |

| Applicable bottle size | 250ml-2000ml |

| Including | bottle rinsing, filling and capping machine 3 in 1 machine |

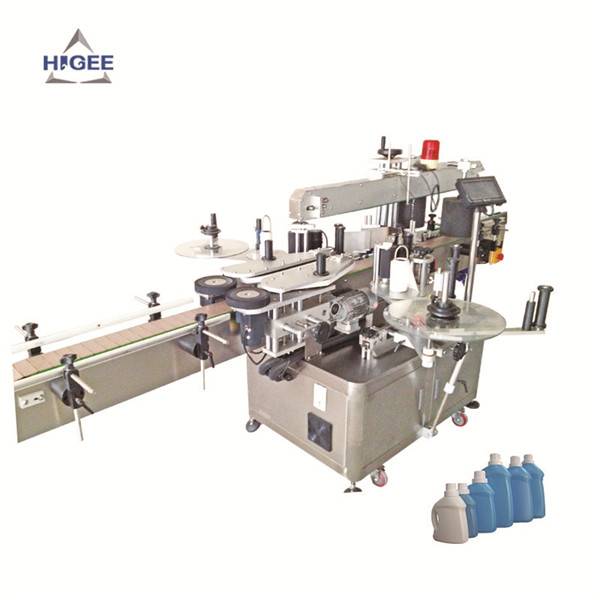

| Complete line options | water treatment system, bottle blowing machine, sticker Labeling machine or sleeve labeling machine, date printer, film wrapping machine etc. |

1. Air conveyor

Material: Stainless steel SUS304

2. Water filling machine (Washing/filling/capping 3-in-1 Monobloc)

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays water to rinse bottle wall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle star wheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and auto rotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through star wheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet

Capping Part

This unit is the highest degree of accuracy of 3-in-1 machine, it is important for the machine to run stably and the product quality.

There is a detector switch in the cap sorter, when the cap is not enough, the detector on the cap sorter get a signal of lacking-cap, the cap elevator starts. The caps in the tank pass through the belt conveyor to the cap sorter. It can change the size of the tank inlet by the flash board; this can adjust the speed of cap falling.

Product detail pictures:

Related Product Guide:

Cooperation

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Factory wholesale Liquid Bottle Filling Machine - Automatic Still Water Filling Machine Line – Higee , The product will supply to all over the world, such as: Orlando, India, Portugal, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.