Factory wholesale Powder Filling Machine - Small Scale Nasal Spray Filling Capping Machine – Higee

Factory wholesale Powder Filling Machine - Small Scale Nasal Spray Filling Capping Machine – Higee Detail:

Automatic Nasal Spray Filling Capping Machine

Features

1. Microcomputer setting, piston pump to perform filling, material contact parts are all high-quality 304 stainless steel, disinfection-free, corrosion-resistant, and high-temperature resistant.

2. The speed of the main engine can be adjusted by stepless frequency conversion.

3. Automatic quantitative control of production volume.

4 The filling execution and the system have the function of sucking back, and the liquid has no dripping.

5. Automatic display technology function, speed can be adjusted at will.

6. Adopt photoelectric control, no bottle no filling, no capping, no capping. Pouring bottle alarm system

7. Fixed torque screw cap, reliable cap screwing quality, no looseness.

8. One machine automatically completes filling, plugging, capping and capping, with fast speed and high degree of automation, which greatly saves labor costs.

9. Color touch screen display, PLC control system.

10. Automatic stop function, it can stop automatically when there is continuous no filling and no inner plug on any track.

11. After filling, when entering the next station, the manipulator will cover it. The capping adopts a manipulator type working cam to rotate the vacuum suction plug cap. The mechanical cam controls the lifting, and the mechanized operation drives the manipulator to stopper and cover, which has the characteristic of no bottle and no outer cover.

12. The capping part adopts constant-torque double-head high-speed capping, and is equipped with an automatic slipping device for tightening, which will not scratch the bottle cap; the bottle does not follow the rotation, and the turntable will not scratch the bottle body, which effectively guarantees the beauty of the packaging material. Touch screen control (the whole machine is controllable), with alarm prompt function.

13. Work flow: Automatically feed the bottle to the station-automatic rotation-automatic quantitative filling-automatic stoppering and plugging-automatic closing and capping (vibration feeding)-automatic capping-finished product Conveyor belt output.

Parameters:

|

Items |

Parameters |

|

Filling head |

1 |

|

Capping head |

1 |

|

Filling volume |

10ml |

|

Production capacity |

40-50 bottles per minute |

|

Air source pressure |

0.6-0.8MPa |

|

Power |

1ph, 110V/50Hz, 1.5KW |

|

Weight |

500Kg |

|

Dimension |

2400*1100*1500mm |

Details

Related Products

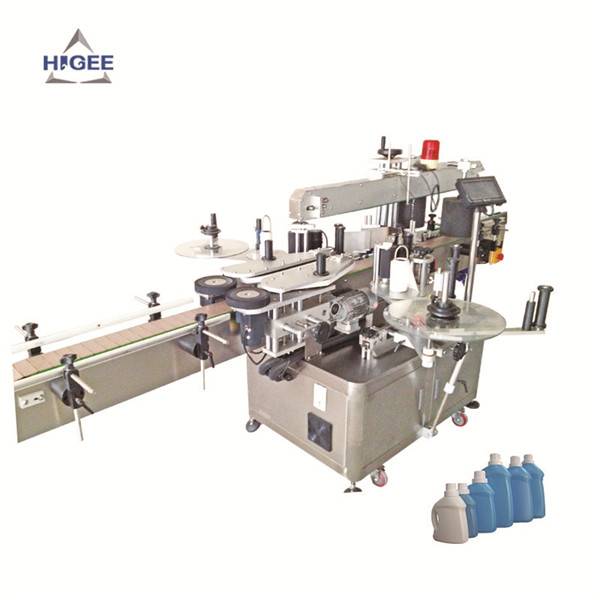

HAY200 Economic Round Bottle Sticker Labeler |

|

Product detail pictures:

Related Product Guide:

Cooperation

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory wholesale Powder Filling Machine - Small Scale Nasal Spray Filling Capping Machine – Higee , The product will supply to all over the world, such as: Thailand, Serbia, Washington, We have developed large markets in many countries, such as Europe and the United States, Eastern Europe and Eastern Asia. Meanwhile with the powerful predominance in persons with ability, strict production management and business concept.we constantly carry on self-innovation, technological innovation, managing innovation and business concept innovation. To follow the world markets fashion, new products are kept on researching and providing to guarantee our competitive advantage in styles, quality, price and service.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.