High definition Induction Cap Sealer - Automatic Linear Capping Machine – Higee

High definition Induction Cap Sealer - Automatic Linear Capping Machine – Higee Detail:

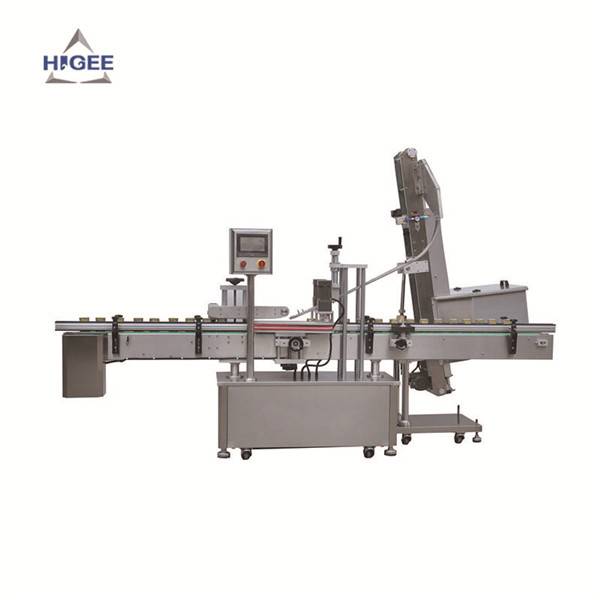

XA10 Automatic linear capping machine

Description

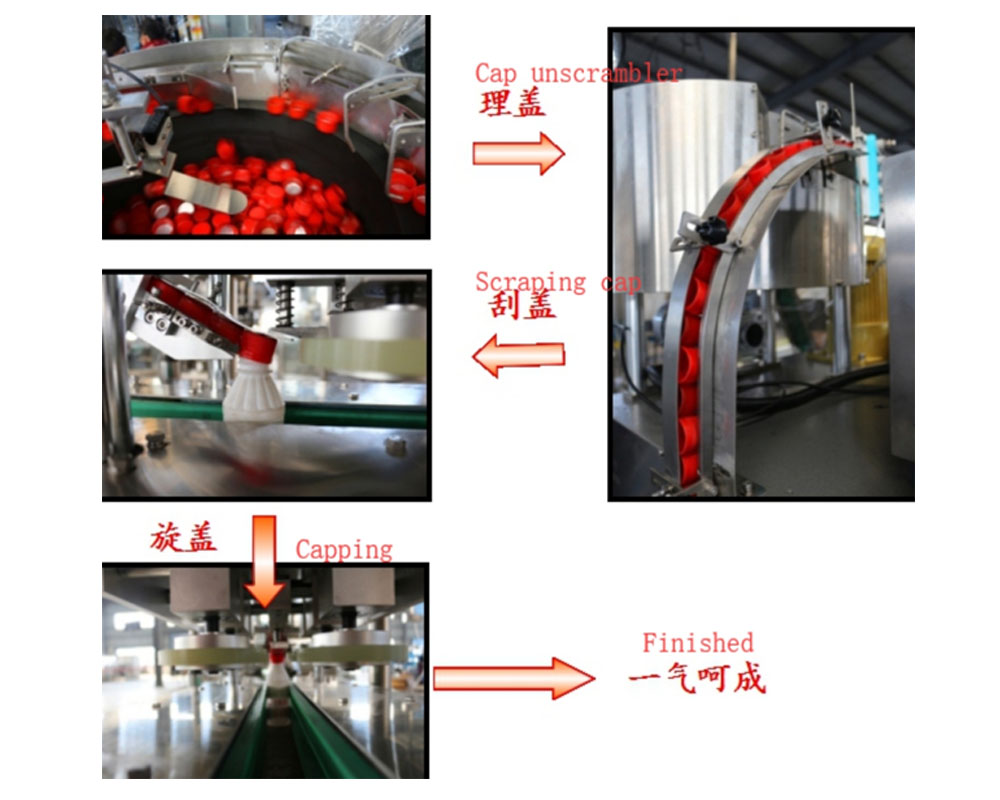

The in-line capping machine comprises a capping unscrambler and a falling cap groove, a bottle clamping conveying mechanism and a capping wheel transmission mechanism. The bottle completes the action of scraping, glanding and capping during horizontal movement under the action of the bottle-carrying belt, and is suitable for the fitting of round caps and flat bottle (pot) screw caps of various materials. The whole machine has a simple structure and convenient adjustment. It is not necessary to exchange accessories when replacing the bottle type, as long as it is adjusted.

(The picture is for reference)

Features

● This operation of the equipment is simple, stable and efficiently.

(The picture is for reference)

● Wide versatility and economic machine

● Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

● Lifting and clamping adjustment adopts plug-in handwheel, which is easy to operate, stable and reliable.

● Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

● The clamping belt is made of a single molded belt for durability.

● The cover wheel is made of beef tendon material, which does not hurt the cover and is durable.

● The intelligent detection reverse cover and the high-speed electromagnetic valve are eliminated, effectively solving the problems of large noise, high gas consumption and low qualification rate, and the adjustment is convenient and fast

Technical Parameter

| Items | Parameters |

| Production capacity: | ≤5000BPH(According to bottles and caps) |

| Bottle: | Φ35-96mm;Height 80-320mm( Be adjusted) |

| Cap: | Φ12-80mm; Height 15-40mm(Be adjusted) |

| Air pressure | 0.5~0.7 Mpa |

| Powder: | 3ph 220V, 50Hz, 2.2Kw |

| Weight: | 650kg |

| Dimension: | 2000×950×2100mm(L×W×H) |

Product detail pictures:

Related Product Guide:

Cooperation

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for High definition Induction Cap Sealer - Automatic Linear Capping Machine – Higee , The product will supply to all over the world, such as: Malaysia, Ghana, America, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.