Hot New Products Shampoo Filling Machine - Cream Jar Filling Capping Machine Line – Higee

Hot New Products Shampoo Filling Machine - Cream Jar Filling Capping Machine Line – Higee Detail:

Main process:

Automatic tube feeder – Liquid filling – automatic cap loader – automatic capping – Horizontal vial labeling machine – output.

Automatic Test Tube Filling Capping Machine

Description

This machine integrates the functions of automatic bottle feeding, automatic positioning, filling, stoppering, and capping. It is widely used in pharmaceutical, biological, daily chemical, chemical and other industries.

Features

1, Touch screen PLC intelligent control, with production counting, no tube filling, no tube no capping, no tube shutdown and overload protection alarm prompt and other functions.

2, The filling head probes to 2/3 of the bottle to start filling, and fills while rising to prevent the liquid from foaming or splashing due to large impact. The filling head guide mechanism ensures that the needle can be inserted into the bottle mouth accurately.

3, Intelligent control of filling quantity: the required filling quantity can be directly input on the touch screen, and the filling quantity can be calibrated with one key. Switching between different specifications makes it extremely convenient to adjust the loading capacity. It reduces the trouble of traditional debugging while debugging.

4, The filling system adopts a modular full quick-connect design, which can be completely disassembled without tools, and is convenient for cleaning and maintenance.

5, Torque-adjustable torque-type manipulator capping mechanism, capping torque can be set on the touch screen, and the capping effect is obviously better than the conventional one. Automatic alarm prompt for unqualified torque.

6, The whole machine is equipped with overload protection and alarm prompt function to monitor the state of the organization in real time. If it is not completed, it will automatically alarm and stop.

Technical parameter

|

Items |

Parameters |

|

Filling volume |

0-5ml (can be customized) |

|

Capacity |

500-1500 (tubes/H) |

|

Power supply |

220V/50Hz, 2kw |

|

Total Weight |

400kg |

|

Dimensions |

2000*1500*1800mm |

Details

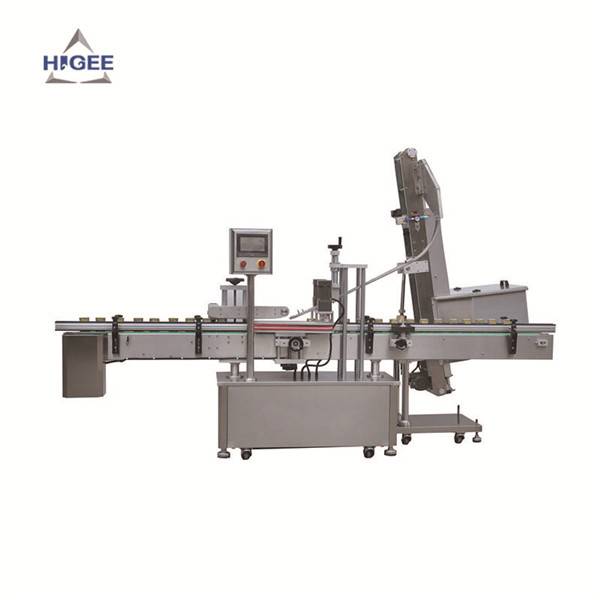

* Horizontal vial labeling machine

Final products

Product detail pictures:

Related Product Guide:

Cooperation

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Hot New Products Shampoo Filling Machine - Cream Jar Filling Capping Machine Line – Higee , The product will supply to all over the world, such as: Norway, Albania, Guyana, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.