Hot-selling Cap Sealing - Automatic Linear Capping Machine – Higee

Hot-selling Cap Sealing - Automatic Linear Capping Machine – Higee Detail:

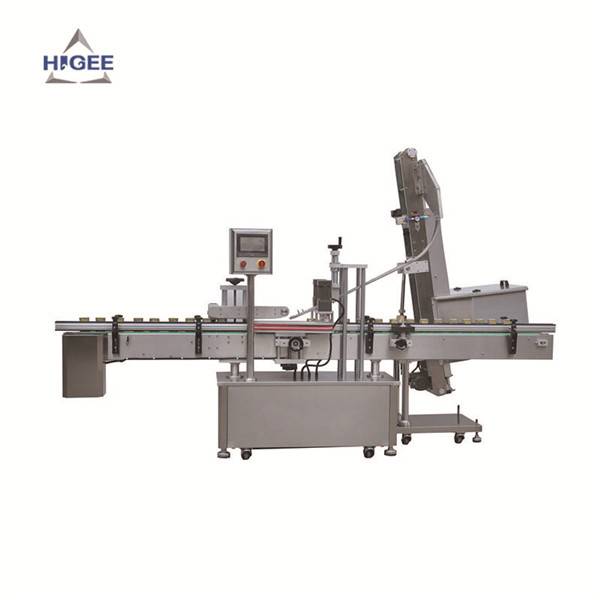

XA10 Automatic linear capping machine

Description

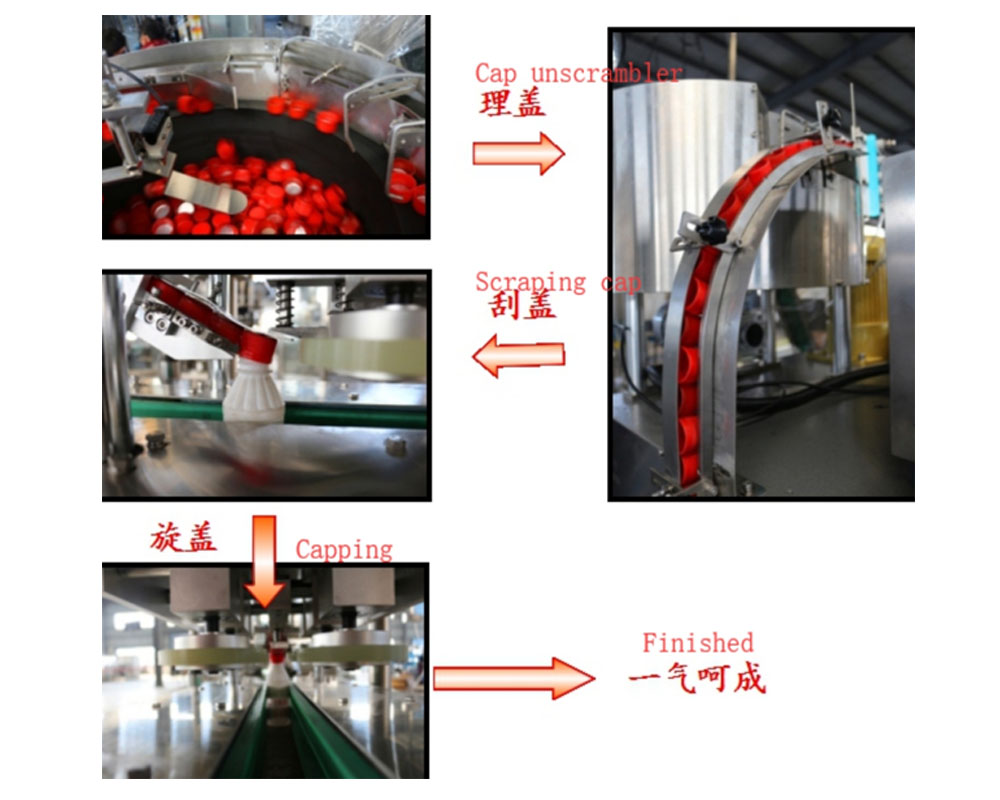

The in-line capping machine comprises a capping unscrambler and a falling cap groove, a bottle clamping conveying mechanism and a capping wheel transmission mechanism. The bottle completes the action of scraping, glanding and capping during horizontal movement under the action of the bottle-carrying belt, and is suitable for the fitting of round caps and flat bottle (pot) screw caps of various materials. The whole machine has a simple structure and convenient adjustment. It is not necessary to exchange accessories when replacing the bottle type, as long as it is adjusted.

(The picture is for reference)

Features

● This operation of the equipment is simple, stable and efficiently.

(The picture is for reference)

● Wide versatility and economic machine

● Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

● Lifting and clamping adjustment adopts plug-in handwheel, which is easy to operate, stable and reliable.

● Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

● The clamping belt is made of a single molded belt for durability.

● The cover wheel is made of beef tendon material, which does not hurt the cover and is durable.

● The intelligent detection reverse cover and the high-speed electromagnetic valve are eliminated, effectively solving the problems of large noise, high gas consumption and low qualification rate, and the adjustment is convenient and fast

Technical Parameter

| Items | Parameters |

| Production capacity: | ≤5000BPH(According to bottles and caps) |

| Bottle: | Φ35-96mm;Height 80-320mm( Be adjusted) |

| Cap: | Φ12-80mm; Height 15-40mm(Be adjusted) |

| Air pressure | 0.5~0.7 Mpa |

| Powder: | 3ph 220V, 50Hz, 2.2Kw |

| Weight: | 650kg |

| Dimension: | 2000×950×2100mm(L×W×H) |

Product detail pictures:

Related Product Guide:

Cooperation

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Hot-selling Cap Sealing - Automatic Linear Capping Machine – Higee , The product will supply to all over the world, such as: Jakarta, Singapore, Miami, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.