Manufacturer for Beer Bottle Filler - Glass Bottle Liquor filling machine line – Higee

Manufacturer for Beer Bottle Filler - Glass Bottle Liquor filling machine line – Higee Detail:

Compete Glass Bottle Whiskey Filler Machine Monoblock Production Line

Features:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

We can also equip the beer production line with water treatment equipment, pre-treatment mixer equipment system, and the packing system including shrink sleeve labeling machine, shrink packing machine etc.as one complete line.

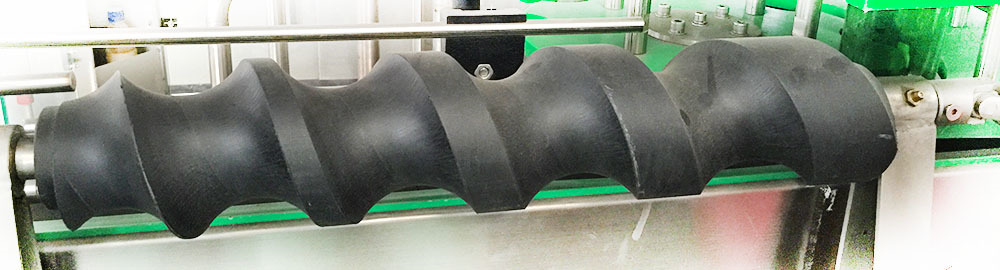

1.Screw Feeder for Glass Bottle

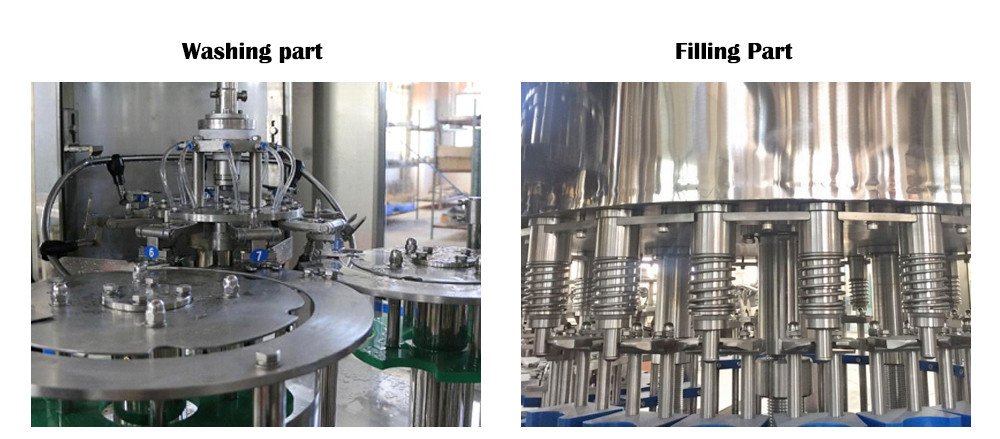

2.Whisky bottle Washing Filling and Capping Machine

whiskey filling machine integrates bottle washing, whiskey filling and capping into one monobloc, and the three processes are carried out full automatically. It is used in the filling of mineral water, pure water, and other non-carbonated beverage(Such as whiskey). For electrical elements, we use Mitsubishi, Omron, Schneider, Airtac, etc. which are famous brand and with assured quality. Each machine element that contacts with the liquid is made of high quality stainless steel. The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor, no bottle no filling, no bottle no capping. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc. The quality reaches the international advanced level. It is the best choice for new and old beverage production line investors.

Feature:

● With bottle neck clipping transmission structure, the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts.

● With Gravity filling theory, filling speed is quick and precision is high; the filling level is adjustable.

● With spring type washing clipper, empty bottles are turned 180°along the guiding roll for inside rinsing; the washing nozzle adopts plum blossom shape multiple holes to rinse the bottle bottom, washing efficiency is high.

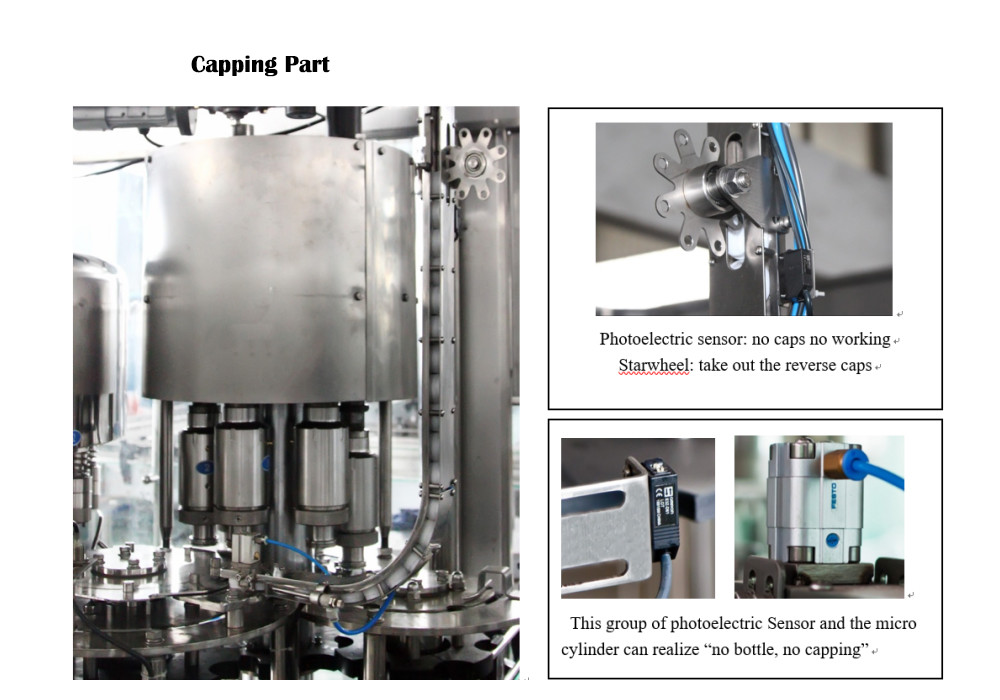

● Capping machine adopts France technology, the capping is by magnet torque; the cap catching adopts twice catching to ensure the veracity. The capping force is adjustable, constant torque capping will not damage caps and the cap is good sealed and reliable.

● The whole machine is operated by touch screen, controlled by PLC and frequency convertor etc., with functions of no bottle no cap feeding, waiting when lack of bottles, stopping if bottle is blocked or no cap in cap guiding pipe.

4.Beer Bottle conveyor

Product detail pictures:

Related Product Guide:

Cooperation

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Manufacturer for Beer Bottle Filler - Glass Bottle Liquor filling machine line – Higee , The product will supply to all over the world, such as: Ottawa, Bogota, Melbourne, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!