Manufacturer for Pill Capsule Filler - Automatic Glass Vial Powder Filling Capping Labeling Line – Higee

Manufacturer for Pill Capsule Filler - Automatic Glass Vial Powder Filling Capping Labeling Line – Higee Detail:

Process

Automatic vial feeding by rotary machine – powder filling – automatic stopper feeding – automatic plugging – automatic cap feeding – automatic cap sealing – automatic transfer to conveyor of labeling machine – wrap around labeling – output

Rotary Feeding Table

Application

This bottle turning table system is applicable to all kinds of cylindrical bottles. It is highly featured by high speed and stable performance. It is always used with the packing line. Besides, the feeding speed is adjustable. If the bottle material is easy to be damaged by the steel surface, we will recommend to add a plastic coating which makes the surface very smooth.

Main Technical Parameters

|

Bottle Type |

5-20ml glass vial |

|

Bottle Size |

D: 20-120mm; H: 30-300mm |

|

Turntable Size |

D: 700 mm (can be customized according to bottle size) |

|

Rotating Speed |

5-48 bottles/min (50ml bottle) |

|

Bottle Feeding Speed |

≤100 bottles/min (can be adjusted) |

|

Power Supply |

AC220V; 50HZ |

|

Power |

0.2KW |

|

Weight |

about 60KG |

Automatic Vial Powder Filling Plugging and Capping Machine

Features

1. This machine is applied for glass vial powder filling,plugger capping machine etc. There is high accuracy cam mechanism to provide Graduated dial to locate the cap on, accelerating cam transmission capping head lifting; constant torsion capping, powder filling; touch screen control, no bottle no filling, no inside and outside cap, with advantage of stable transmission, accurate location, accurate dosing, convenient operation etc.

2. This filling system is widely suitable for small bottle filling and capping,which is complied with GMP standard.

Main technical parameter

Capacity: 20-40bottles per minute

Filling heads: 1 heads

Filling volume: 5-20ml

Rubber head: 1

Capping heads: 1

Filling accuracy: ±0.05% per time

Power supply: single phase, 220V 50Hz

Pow er consumption: 1.8kw

Size: about 2000mm x 1500mm x 1800mm

Details

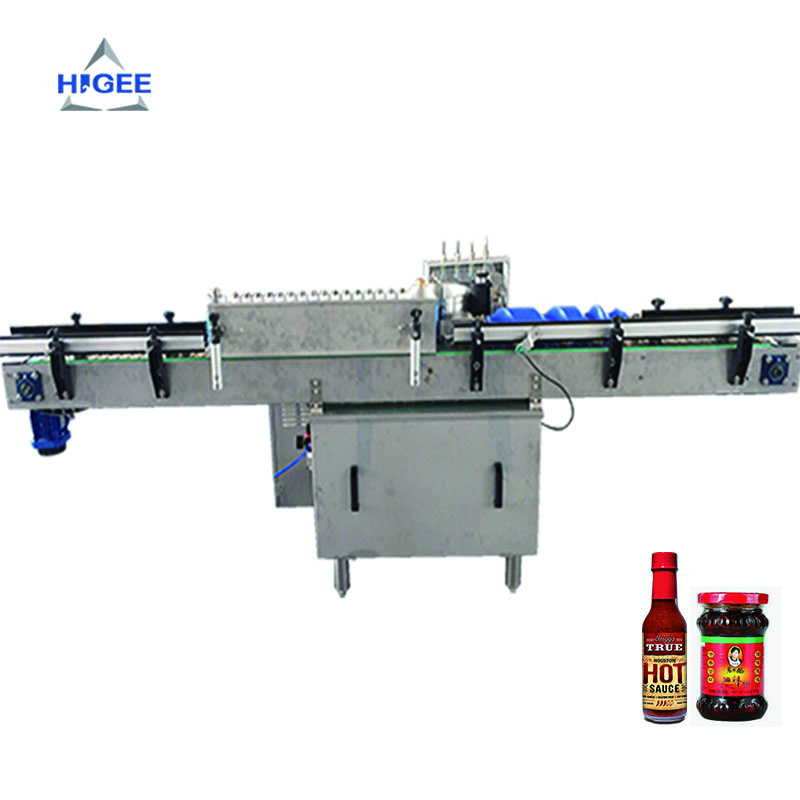

Automatic Round Bottle Labeling Machine

Suitable products

*Example of some suitable products

Product detail pictures:

Related Product Guide:

Cooperation

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Manufacturer for Pill Capsule Filler - Automatic Glass Vial Powder Filling Capping Labeling Line – Higee , The product will supply to all over the world, such as: Pretoria, French, Sevilla, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!