Oil flling machine line

Oil Filling Capping Machine Linear Line

1.Automatic Oil Filling Machine

Application:

Oil, cream, jam, detergent, and other highly viscous material in beverage, food, chemical, pesticide, medical, commodity, and many other industries.

Features:

● Accurate Volume: Servo system is applied ensure the high accuracy of the filling volume.

● Changeable Speed: The filling speed will become slower automatically when approaching the intended volume.

●Submerged Filling: Filling nozzles will submerge in the liquid while filling to avoid foaming and spilling.

● Intelligent Adjustment: You only need to change the parameters on the touch screen for different filling volume or even fine tuning. All filling heads can be adjusted. It has user-friendly interface and is really easy to operate.

●Pollution-free: The main frame of the machine is made of high-quality stainless steel 304 with good anti-corrosive effect. All contacting parts are made of stainless steel 316L. The whole machine is sealed with stainless steel and toughened glass so that waste gas leak will be prevented.

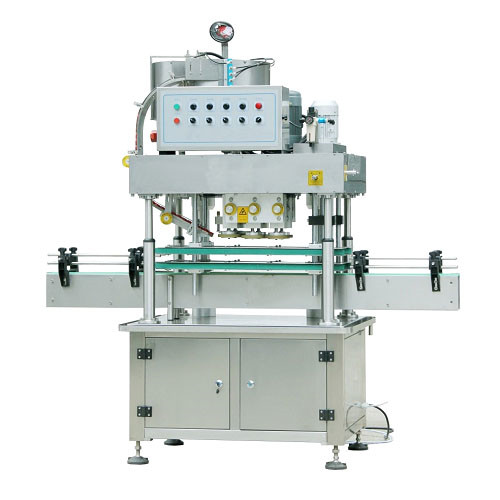

2.Automatic Twisting Capping Machine

Features:

This type of capping machine is widely used for the capping of round, square, or flat bottles with a screw cap.

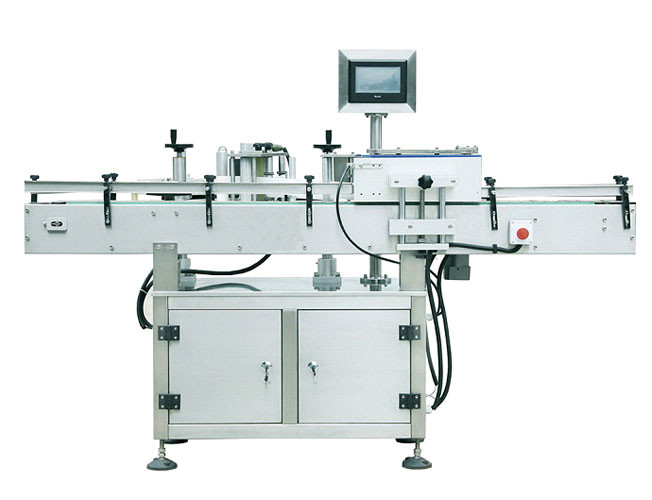

3.Automatic Sticker Labeling Machine

Features:

This type of labeling machine is widely used for the labeling of round bottles with adhesive stickers. It is controlled by PLC and driven by servo. The user-friendly interface makes it quite easy to operate.

1. The independent electromechanical label rolling structure synchronizes the rolling and labeling processes, thereby improving the labeling accuracy.

2. There is an instruction on the machine showing how the label film convolves so that changing the film becomes easy.