PriceList for Filler Capper - Automatic Glass Bottle Water Filling Machine Line – Higee

PriceList for Filler Capper - Automatic Glass Bottle Water Filling Machine Line – Higee Detail:

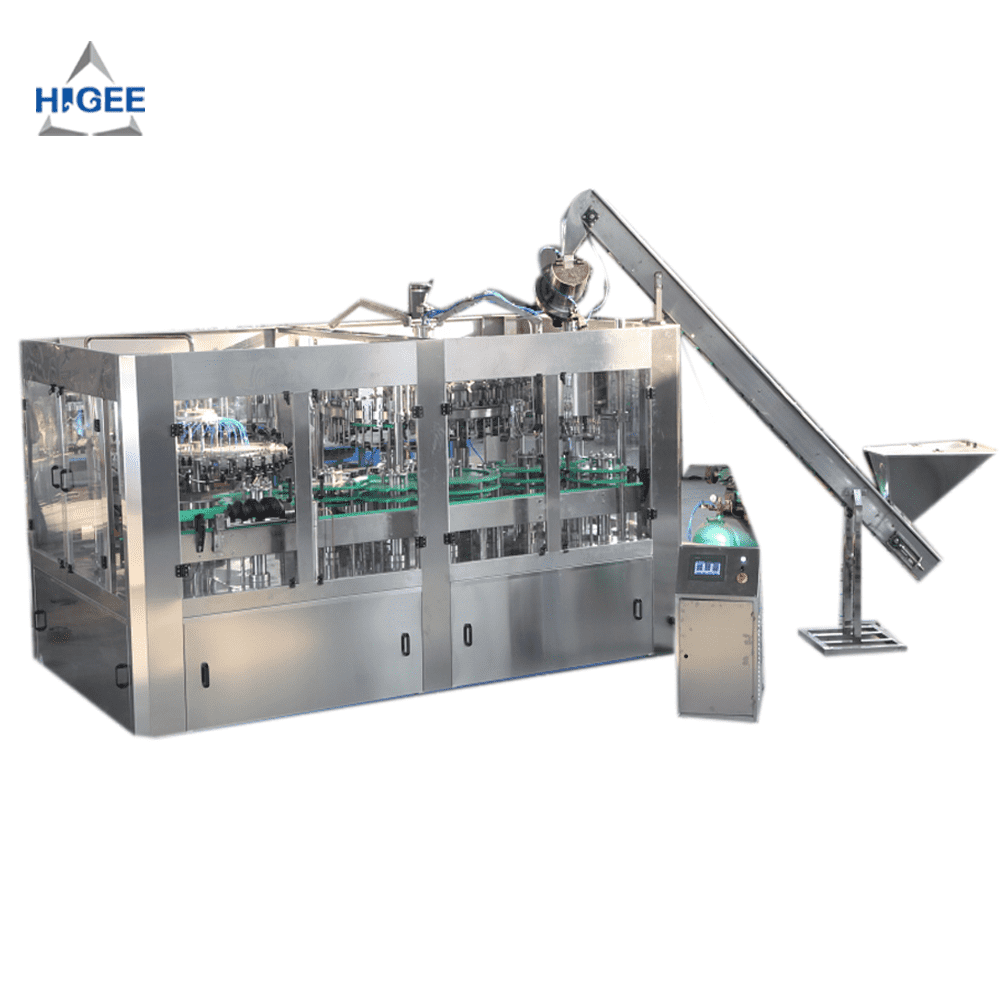

Glass bottle Water 3 in 1 Rinsing Filling and Capping Machine

Featured:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

Parameters:

| Capacity range | 2000BPH-18000BPH (based on 500ml bottle) |

| Applicable bottle size | bottle height 160-340mm, diameter ∅50mm-∅100mm |

| Including | bottle rinsing, filling and capping machine 3 in 1 machine |

| Complete line options | water treatment system, bottle blowing machine, sticker Labeling machine or sleeve labeling machine, date printer, film wrapping machine etc. |

Glass bottle Water 3 in 1 Rinsing Filling and Capping Machine

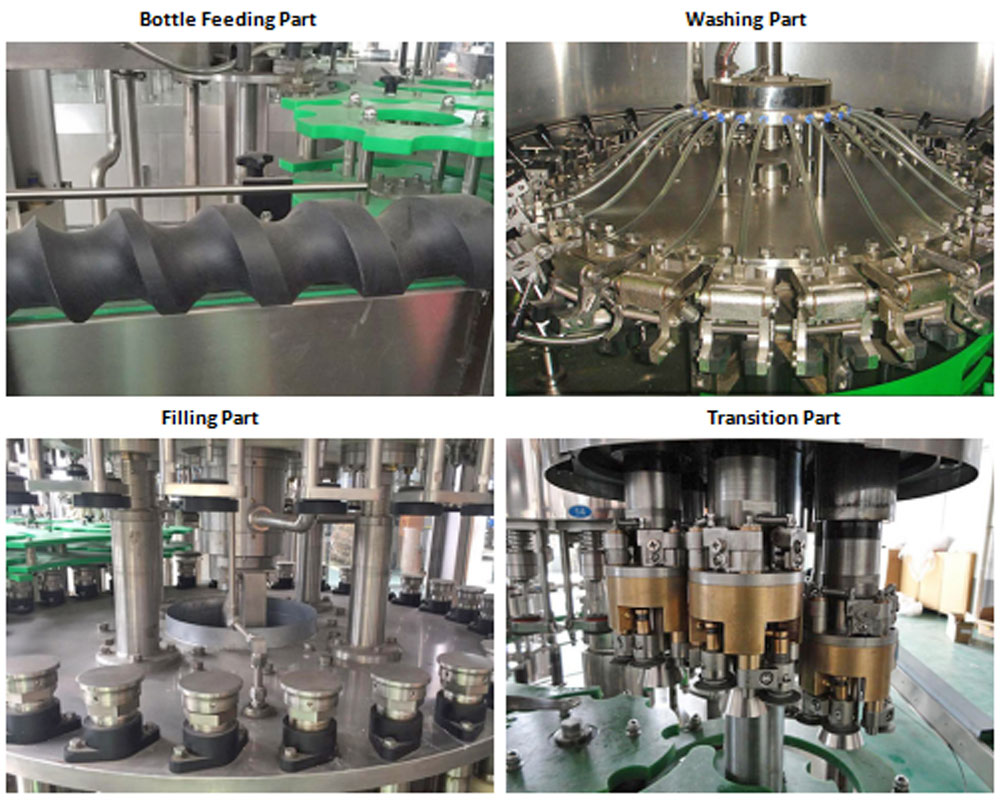

1)Spring-type flushing pliers, the empty bottle automatically turns 180° with the track, and the bottle is rinsed. The plumbing nozzle of the machine adopts plum-shaped multi-holes to flush the angles of the bottom of the bottle, and the flushing efficiency is high.

2)Adopt bottle bottom holding and micro-negative-pressure filling type. The filling level is steady and speed stable, without leakage.

3)Adopt alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places. The device helps to ensure the quality of its production.

4)Easy operation. For the bottles with same diameter but a little difference in height, the 3in1 monoblock do not need changing exchanging parts. It just needs to adjust height of drying/filling/capping valves, so that time is saved and maintenance more convenient.

5)Independent electricity box makes sure every electrical appliance works smoothly.

6)Material: The material which contact directly with the liquid is the SUS304 (Food grade), made in china.

Product detail pictures:

Related Product Guide:

Cooperation

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for PriceList for Filler Capper - Automatic Glass Bottle Water Filling Machine Line – Higee , The product will supply to all over the world, such as: Plymouth, New Orleans, Denmark, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!