Water treatnebt system - Water treatnebt system – Higee

Water treatnebt system - Water treatnebt system – Higee Detail:

Compete Glass Bottle Beer Filler Machine Monoblock Production Line

Features:

The machine elements that contact with the liquid is made of high quality stainless steel, The critical components are made by numerically-controlled machine tool, and the whole machine condition is under detection by photoelectric sensor. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

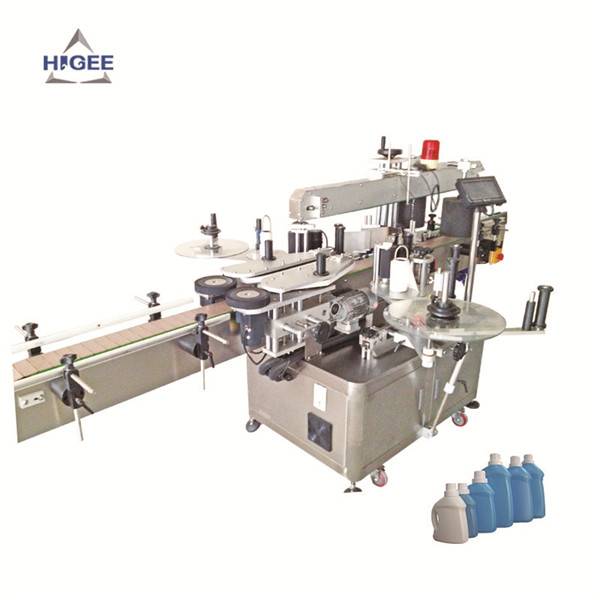

We can also equip the beer production line with water treatment equipment, pre-treatment mixer equipment system, and the packing system including shrink sleeve labeling machine, shrink packing machine etc.as one complete line.

1.Beer Bottle Screw Feeder

2.Beer bottle Washing Filling and Capping Machine

This Beer filling equipment adopts bottle neck holding transmission technology to realize fully automatic washing, filling and capping. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation, etc.

Features:

● with bottle neck clipping transmission structure, the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts.

● with Isobaric filling theory, filling speed is quick and precision is high; the filling level is adjustable.

● With spring type washing clipper, empty bottles are turned 180°along the guiding roll for inside rinsing; the washing nozzle adopts plum blossom shape multiple holes to rinse the bottle bottom, washing efficiency is high.

● Capping machine adopts France technology, the capping is by magnet torque; the cap catching adopts twice catching to ensure the veracity.The capping force is adjustable, constant torque capping will not damage caps and the cap is good sealed and reliable.

● The whole machine is operated by touch screen, controlled by PLC and frequency convertor etc., with functions of no bottle no cap feeding, waiting when lack of bottles, stopping if bottle is blocked or no cap in cap guiding pipe.

4.Beer Bottle conveyor

Product detail pictures:

Related Product Guide:

Cooperation

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for Water treatnebt system - Water treatnebt system – Higee , The product will supply to all over the world, such as: Slovenia, Sri Lanka, India, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!