Wholesale Auger Filling Machine - Aseptic Nasal Filling Capping Machine – Higee

Wholesale Auger Filling Machine - Aseptic Nasal Filling Capping Machine – Higee Detail:

Liquid Filling Capping Machine with Flow Hood

Working principle

Cap feeding mechanism: the bottle moves intermittently to the capping station through the turntable, and the capping turntable is controlled by the optical fiber detection to control the working signal of the capping servo motor, so as to achieve the function of capping with a bottle and no bottle, no capping. The capping mechanism is designed on the principle of double-arm manipulator, which avoids the instability of the previous spring or single-arm manipulator after long-term use. The whole process of capping does not require air source and vacuum, and the capping part has an automatic positioning function, which is stable, no pollution, accurate positioning.

Capping mechanism: The first capping mechanism adopts a constant torque design, and the torque is adjusted according to the tightness of the thread of the bottle cap and the bottle mouth. After the capping is in place, it can automatically slip. The purpose of hurting the bottle. The second bottle positioning is automatically positioned by mechanical transmission, clamping without pneumatic components, stable bottle clamping, and no damage to the bottle surface.

Features

- The machine adopts a unique mechanical capping mechanism, the capping is accurate.

- With the function of no bottle, no filling, no bottle, no capping.

- With emergency stop switch, automatic alarm when mechanical failure occurs. Equipped with a wireless remote control debugging device, which is convenient for equipment maintenance and debugging.

- Submersible filling without dripping or foaming.

- The filling needle is smooth and ground with R60 degree inner chamfer and does not hang liquid.

Technical parameter

|

Items |

Parameters |

|

Applicable bottle |

5-50ml round plastic bottle, glass bottle |

|

Production capacity |

10ml: 80-100 bottles/min |

|

Filling method |

Peristaltic pump |

|

Filling station |

2 |

|

Filling accuracy |

≤ ±2% |

|

Capping pass rate |

≥ 99% |

|

Power supply |

220V 50HZ |

|

Power |

3kw |

|

Dimensions |

2000×1500×2100mm (subject to actual size) |

|

Weight |

700kg |

Details

Suitable products

Related Product

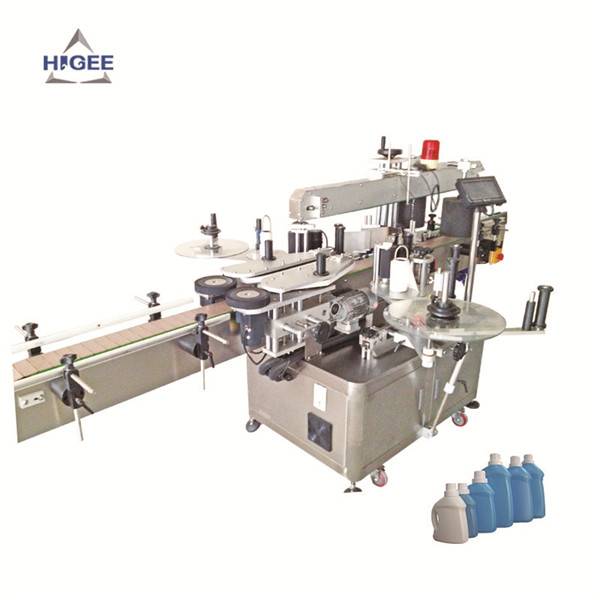

HAY Round Bottle Labeling Machine (Optional: Bottle Collection Table)

Product detail pictures:

Related Product Guide:

Cooperation

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Wholesale Auger Filling Machine - Aseptic Nasal Filling Capping Machine – Higee , The product will supply to all over the world, such as: Argentina, Algeria, Portugal, The president and all the company members would like to provide professional products and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.